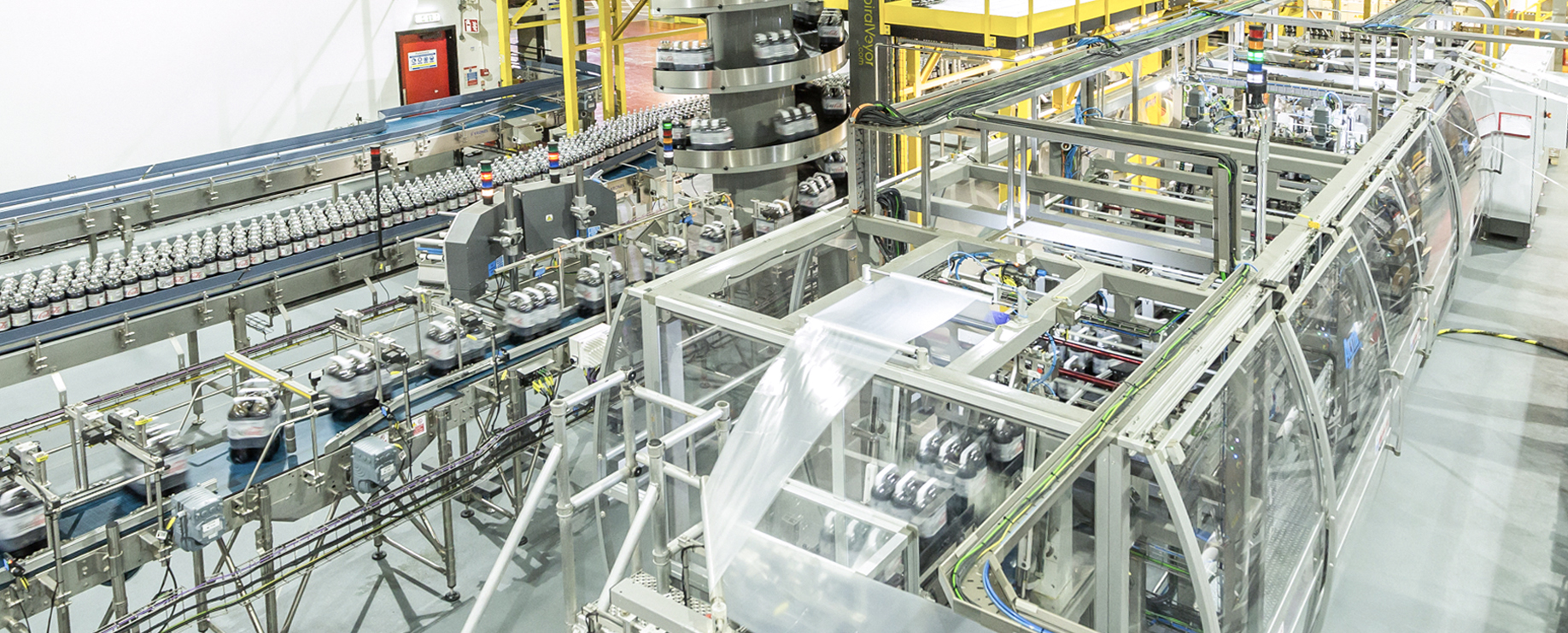

CARTON CONVEYOR BELTS

The carton conveyor belts produced by ACMI are supplied with high-efficiency motors and are equipped with some devices to preserve the cardboard box from rubbing and friction. They are fitted with quick-adjusting guides and, upon request, they can be equipped with automatically adjusting guides and very fast format changeover times. They are managed by proprietary algorithms, which maximise their operating efficiency, and can be equipped with various systems for handling cartons such as pack turners, 90° deviators and plate dividers.

DETAIL