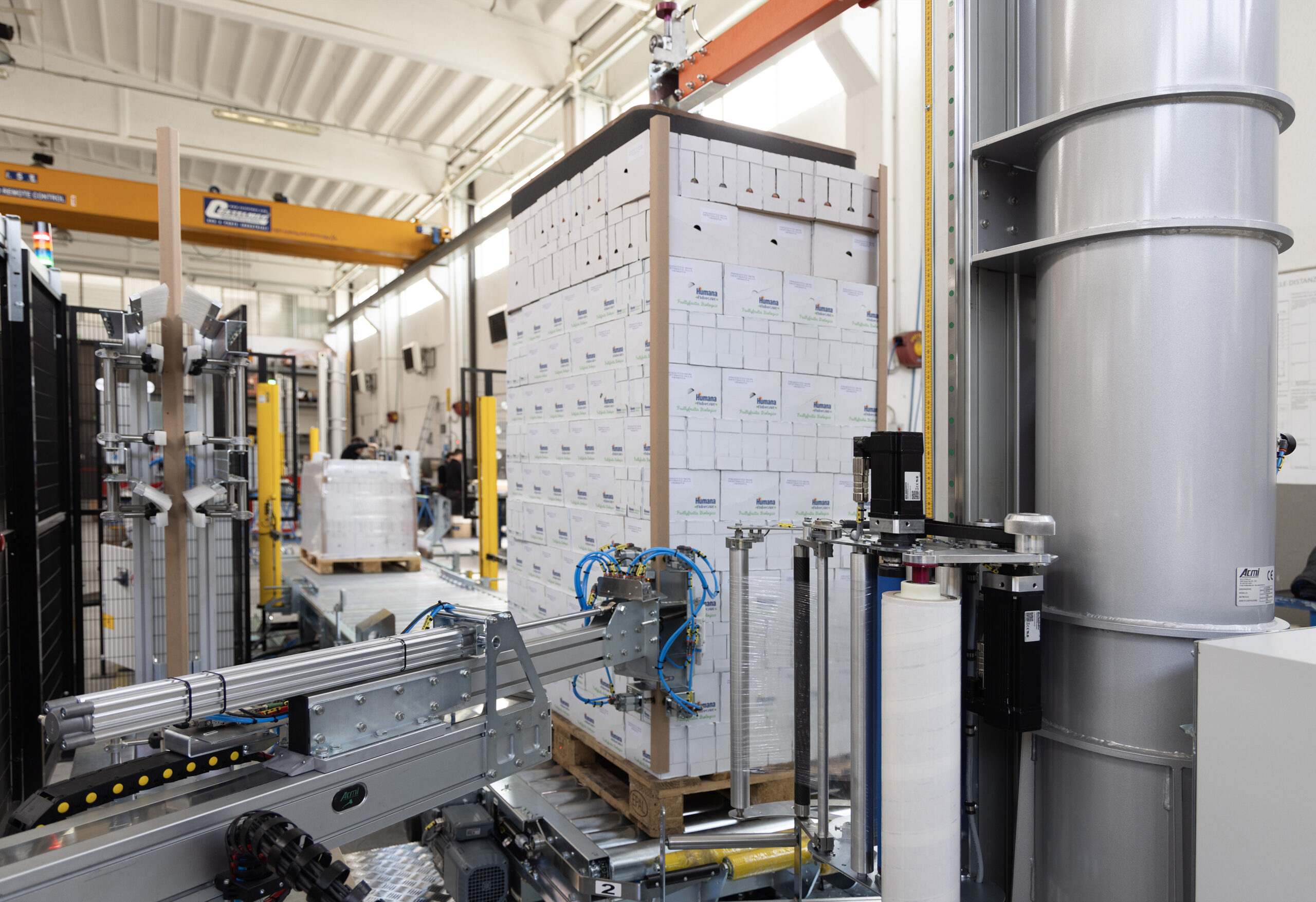

ROCKET

Rocket is a rotating pallet stretch wrapper with a SCARA-type robotic structure designed by ACMI. The machine is equipped with an electronic pre-stretch system capable of exceeding values of 400% (if the film allows it) and of handling very thin films, of even less than 25 microns. The electronic pre-stretch of the Rocket stretch wrapper allows the complete personalisation of the wrapping cycle and the formation of holding ropes. It is a very flexible machine that can mount reels of 500, 750 and 1,000 millimetres and can be equipped with different systems to increase its performance: automatic changeover system of the entire pre-stretch unit; top cover system; hermetic wrapping system; external welding station. The ideal production range for Rocket is 60 to 180 pallets per hour.

DETAIL