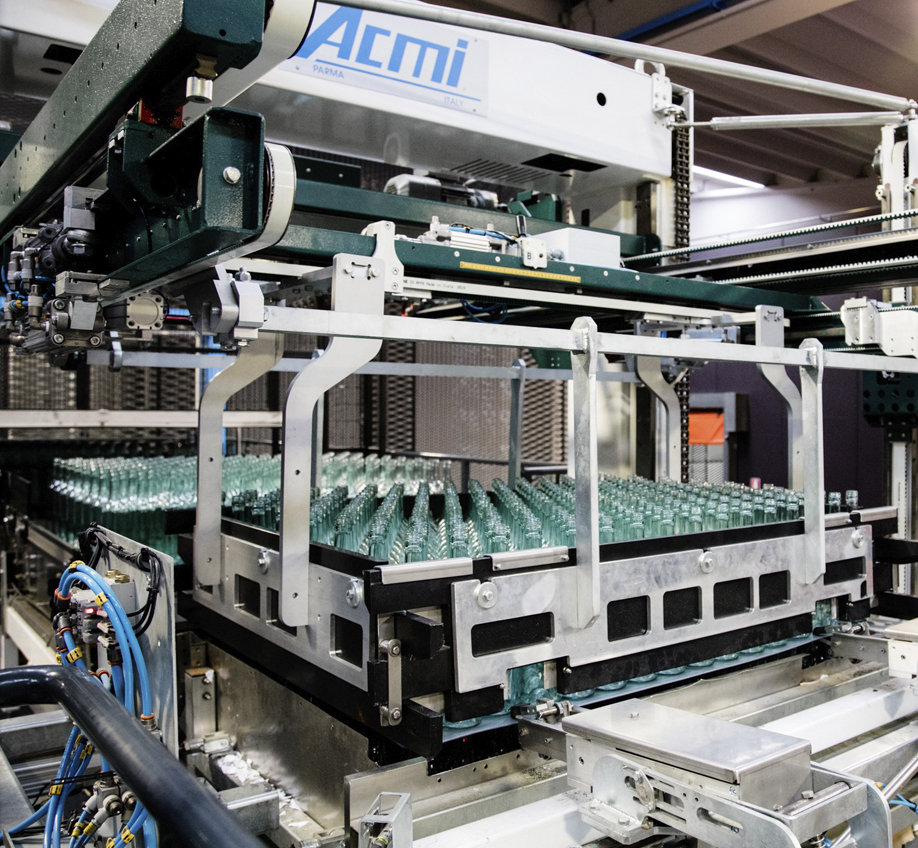

RASAR D200

Rasar D200 is a traditional depalletiser with a sweep-off gripping system and a low-level product infeed. The machine is equipped with an independent centering device which holds the layer underneath the one being transferred and it can be configured with the high-level or low-level unloading. The depalletisation speed of Rasar D200 is about 29,000 bottles and 73,000 cans per hour.

DETAIL