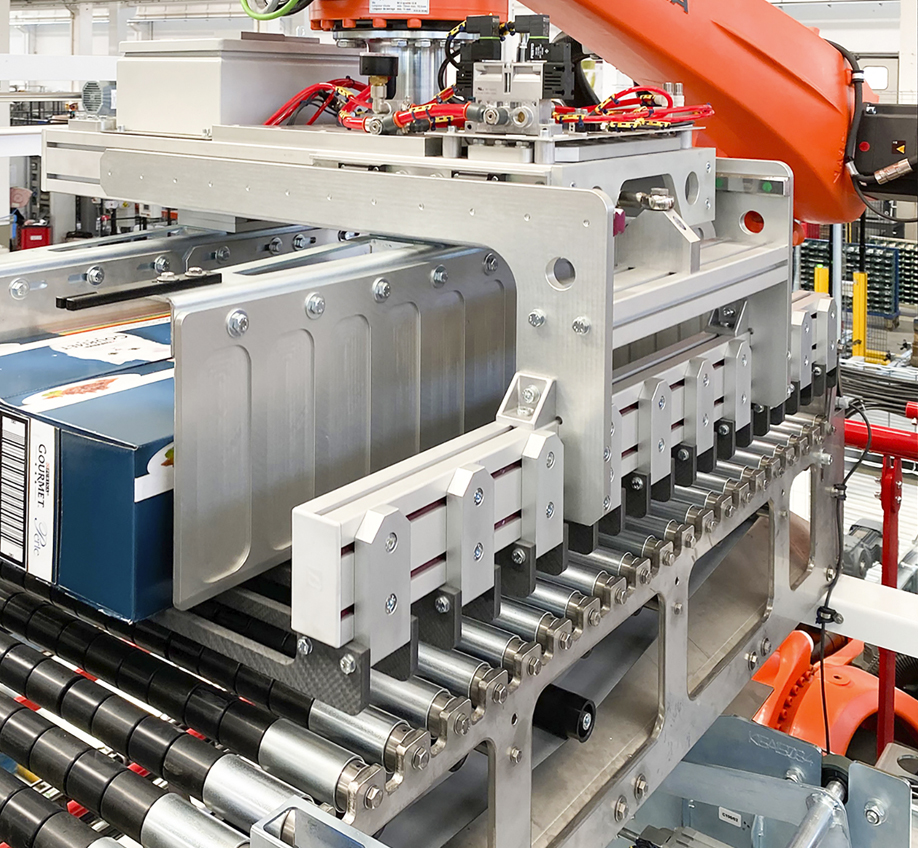

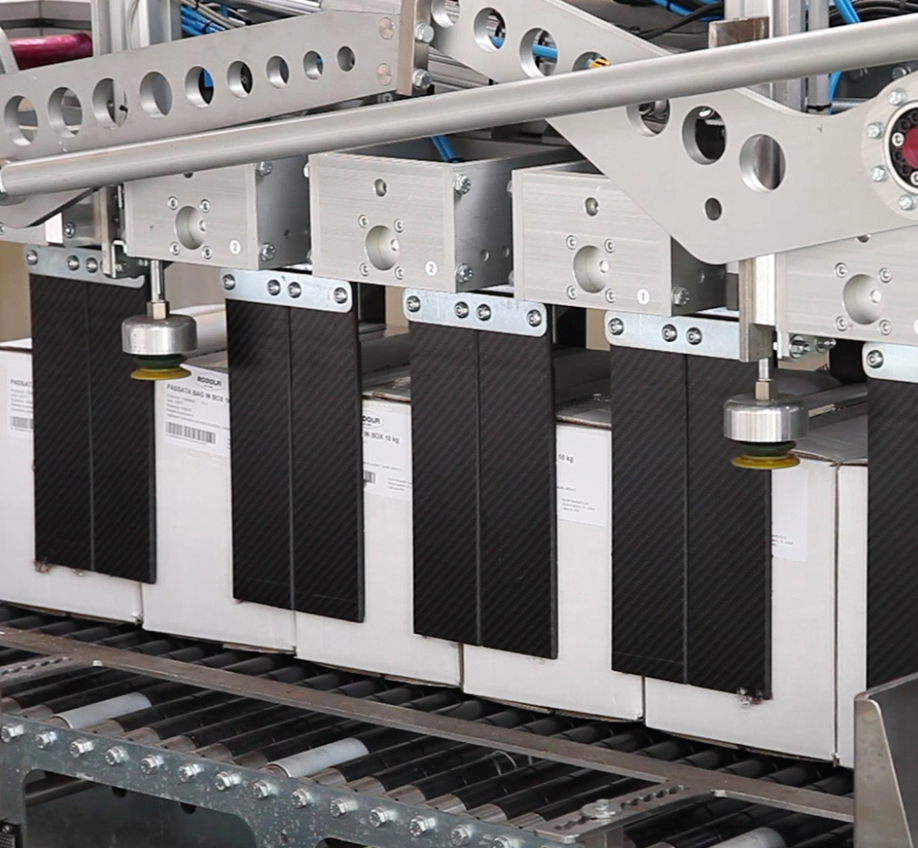

CONDOR P140

This is a high-speed robotic palletising system consisting of the Condor robot and the Twisterbox layer formation system. The simple construction, the great accessibility guaranteed by the robotic structure and the new double-comb palletising head make this machine the ideal solution for lines that reach productions of 84,000 bottles and 110,000 cans per hour. This system is also particularly suitable for Repacking lines and GoGreen lines.

DETAIL