References

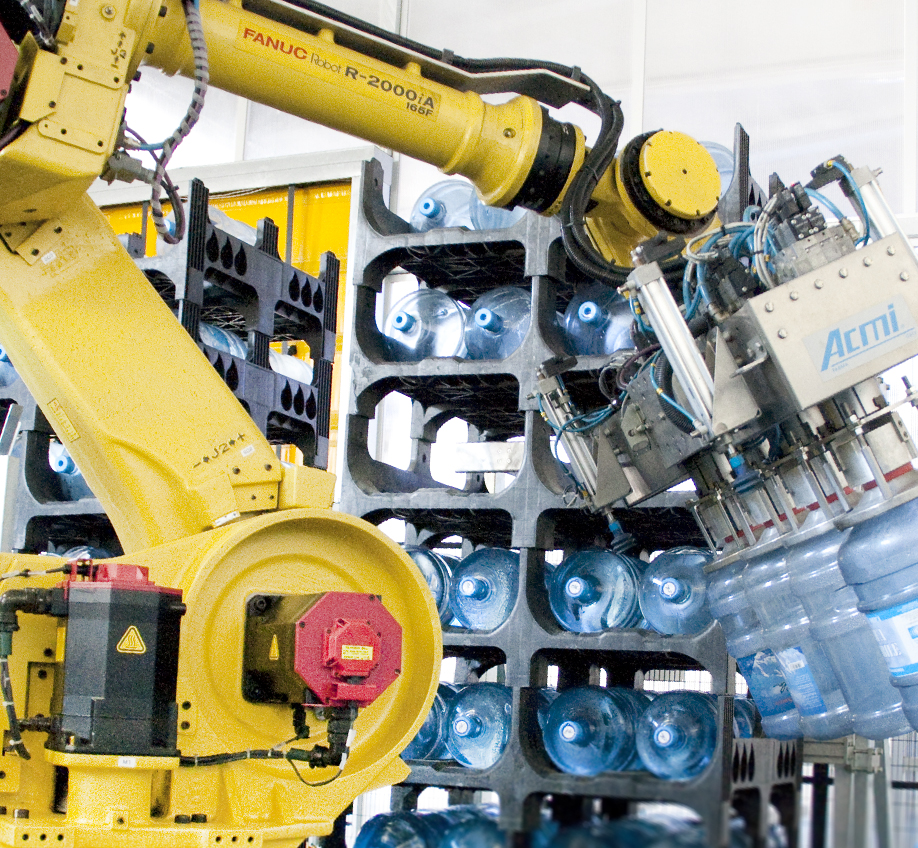

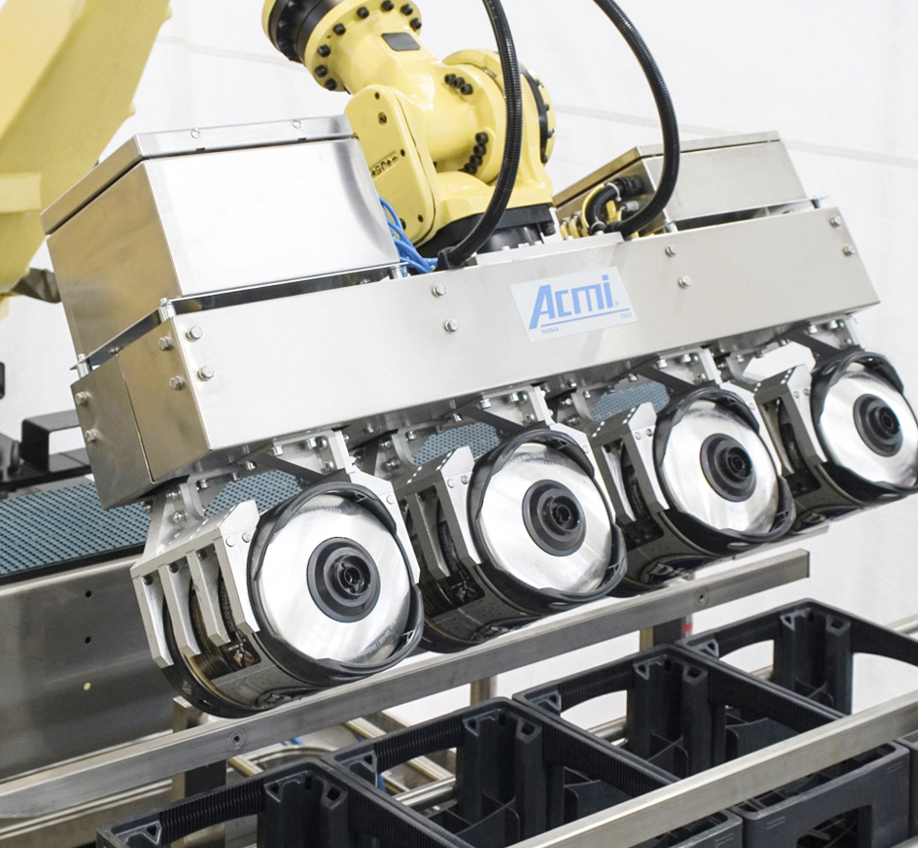

In this section of the website we have collected a series of installations representative of ACMI’s ability to design and build innovative packaging and bottling lines. For each installation there is a brief description of the project. If you would like to receive more information, you can contact us using the form at the bottom of the page.